FINE

BLANKING

Fine Blanking – The Leading Edge

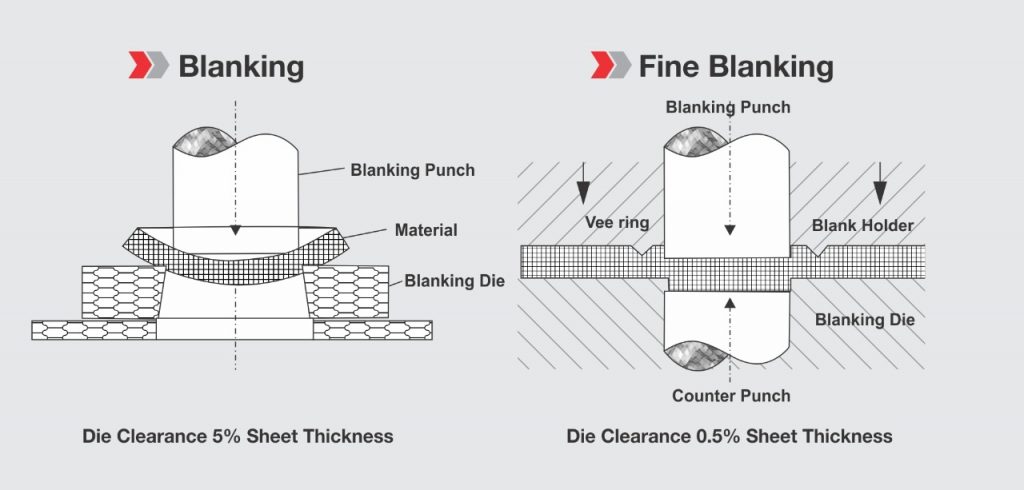

Fine Blanking is a metal forming process used to produce ‘Net Shape’ finished parts in single operation or with minimal secondary processing. Hydraulic presses are used to actuate the tool and die in three motions, thus makes clear shear with straight edges with no fracture zones, good flatness tolerances and high level of angular accuracy. Comparing to conventional stamping process, the die clearance in Fine Blanking process is one tenth, which eliminates the tearing on the cut edges of the parts

Advantages of Fine Blanking Process

- Automated high speed press process

- Reduced requirement of secondary operations

- High volume of production

- Producing close tolerances finished components

Types of geometry that Fine Blanking Process can produce

- Intricately shaped holes

- Slots and projections

- Coining and thinning

- Forming

- Shallow chamfers

- Semi-pierces

- Pockets

- Counter bores and countersinks

- Bends and offsets

| FINE BLANKING | CONVENTIONAL BLANKING |

|---|---|

| 100% Clean sheared edges | Edges are not 100% clean |

| Surface finish can be achived up to 0.8 microns | Not Possible |

| Better wear resistance at edges | Poor wear resistance at edges |

| Excellent flatness ie., no material deformation while blanking | Material deformation occurs |

| Small, pierced holes relative to material thickness can be achieved | Not possible |

| Reduces or Eliminates costly secondary operations | Not possible |

| Tight dimensional tolerances can be achieved | Not possible |

LGB is fully equipped to meet your demands for both Fine Blanking and creative forming so that you get the advantage of cost savings, reduced process time, fast operations and parts that are of outstanding flatness and dimensional accuracy. The Fine Blanking tool is a specially designed complete press tool with a V-ring and an extremely small punch-die clearance. LGB brings to bear its expertise in all areas of operation right from Raw Material, Tool engineering, Process design, to give customers the very best Fine Blanked Parts & Assemblies.

LGB’s array of Fine Blanking presses offer a wide range of tonnage from 100 tons to 1000 tons.

| S.No. | Tonnage | No. of Presses |

|---|---|---|

| 1 | 100 | 1 |

| 2 | 160 | 1 |

| 3 | 200 | 1 |

| 4 | 250 | 10 |

| 5 | 320 | 3 |

| 6 | 400 | 5 |

| 7 | 650 | 2 |

| 8 | 710 | 1 |

| 9 | 1000 | 1 |

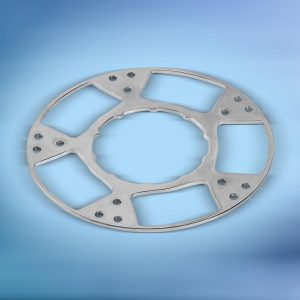

Our products range from 1 mm to 12 mm thickness.

Products as diverse such as automobile parts, electrical parts, textile parts are blanked in our plant. Our systems allow us to coordinate scheduling and production, while maintaining strict Quality Control for every component.

LGB has established a modern laboratory for checking various components to ensure meeting International standards.

Central function and all Fine Blanking factories are certified with ISO /IATF 16949:2016.

We Fine Blank following materials

| Ferrous Materials | Non Ferrous Materials |

|---|---|

| Low Carbon Steels | Copper |

| Medium Carbon Steels | Phosphor Bronze |

| Spring Steels | |

| Alloy Steels | |

| Stainless Steels |

SPECIAL PROCESSES

WELDING

- Plasma Arc Welding

- MIG Welding

- TIG Welding

- Spot Welding

- Rotary Welding

SURFACE COATING & PLATING

- Zinc Nickel Platting

- Zinc Platting

- Manganese Phosphating

- Zinc Phosphating

- Nickel Plating

- PTFE Coating

- Blackening

- MoS2 Coating

HEAT TREATMENT

- CarboNitrding

- Case Carburizing

- Through Hardening

- Nitro Carbonating

- Induction Hardening

- Induction Softening

- Liquid Nitriding

MOULDING

- Plastic Over Moulding

- Rubber Over Moulding

Gallery

Previous

Next

Esteemed Clients